Seamless alloy steel pipe

Prime European, Japanese, and North American manufacturers.

Fast despatch from stock.

Single random, double random or fixed lengths

Additional testing can be arranged, as required.

A333 Grade 3 Pipe 3.5% Nickel

ASTM/ASME A/SA 333 Grade 3 Pipe 3.5% Nickel

We stock seamless pipe 1/2" up to 18" for Low Temperature service and other other applications with required notch toughness.

Our range covers wall thicknesses s20 through to s160, STD (Standard), XS (Extra Strong) and XXS (Double Extra Strong). Availability determined by diameter.

All seamless pipe is ordered dual certified according to ASTM/ASME A/SA 333/3, with additional requirements to MESC SPEC 74/004.

Certification is EN10204 3.1 and conforms to NACE MR-01-03, NACE MR-01-75 and PED 97/23/EC. All pipe is impact tested at -101°c with minimum single values of 21J and a minimum average of 27J. We also have a range of pipes which are additionally impact tested at -105°c.

| Element | Composition % |

| Carbon | 0.19 MAX |

| Manganese | 0.31-0.64 |

| Phosphorus | 0.025 MAX |

| Sulfur | 0.025 MAX |

| Silicon | 0.18-0.37 |

| Nickel | 3.18-3.82 |

| Tensile Requirements | ||

| psi | MPa | |

| Tensile Strength, min | 65 000 | 450 |

| Yield Strength, min | 35 000 | 240 |

ASTM/ASME A/SA 671

We also carry Welded pipe which is a direct equivalent of A333 Grade 3, currently with a limited number of sizes and wall thicknesses from 18" to 36" according to A671 CF66 (A203 CF65 Gr.D)

| Element | Composition % |

| Carbon | 0.17 MAX |

| Manganese | 0.70 MAX |

| Phosphorus | 0.035 MAX |

| Sulfur | 0.035 MAX |

| Silicon | |

| Heat analysis | 0.15-0.40 |

| Product Analysis | 0.13-0.45 |

| Nickel | |

| Heat Analysis | 3.25-3.75 |

| Product Analysis | 3.18-3.82 |

| Tensile Requirements | ||

| ksi | MPa | |

| Tensile Strength, min | 65-85 | 450-485 |

| Yield Strength, min | 37 | 255 |

Click here to send us an enquiry or request further information.

Pipes »

ASTM A335 P11, P22, P5, P9 & P91

ASTM A333 Gr3 (Low Temp 3.5% Nickel)

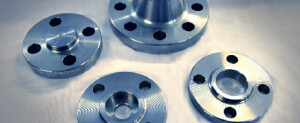

Flanges »

ASTM A182 F11, F22, F5, F9 & F91

ASTM A350 LF3 (Low Temp 3.5% Nickel)

BW Fittings »

ASTM A234 WP11, WP22, WP5, WP9 & WP91

ASTM A420 WPL3 (Low Temp 3.5% Nickel)

Forged Fittings »

ASTM A182 F11, F22, F5, F9 & F91

ASTM A350 LF3 (Low Temp 3.5% Nickel)

Get in touch

Thank you

Thank you for your enquiry, we will be in touch soon.